3D-printed breast phantom: visual inspection and physical evaluation

The physical breast slice was 3D printed successfully without visible printing surface defects (Fig. 2a). This was achieved despite the limitations of the BambuLab X1C to print objects combining PLA and ABS filaments.

The measured thickness of the printed slice was 1.110 ± 0.005 cm (1% thicker than nominal value). The 2D image (Fig. 2b, c) shows that the PLA-ABS interfaces are free of air artifacts and the infill pattern is barely visible (Fig. 2b, c).

Effective attenuation coefficient of breast 3D-printed phantom materials: benchmark with tissue-equivalent materials

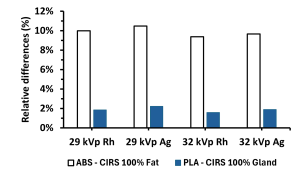

The µeff values for 3D-printed materials (PLA and ABS) for the different acquisition conditions were collected in Table 1 and relative differences between these values and those of reference materials were shown in Fig. 3. For the selected acquisition conditions, relative differences between µeff values of 3D-printed and reference materials (Fig. 3) were 2% average (1% to 3% range) for PLA – CIRS 100% Gland, and 10% average (8% to 11% range) for ABS – CIRS 100% Fat.

[tab]1[/tab]

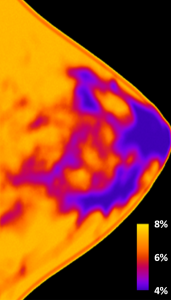

In the thickness differences map shown in Fig. 4, the relative differences were 7% average (6% to 8% range). Higher differences were found in ABS regions than in PLA regions, as the shrinkage of ABS is higher than that of PLA, presenting a lower thickness accuracy compared to the digital model. An additional contribution to such differences in both materials may be due to the existence of air micro-gaps between the deposited layers of material, which is common in FDM.